Grasping In-Mold Decorations: Strategies, Fads, and Finest Practices for Ideal Outcomes

In the world of manufacturing, the art of in-mold decors stands as a crucial aspect of product layout and production. As sectors constantly seek cutting-edge means to enhance visual appeal and functionality, understanding the complexities of in-mold decorations has arised as a crucial skill set. From selecting the best materials to including cutting-edge layout fads, the journey in the direction of accomplishing ideal lead to this domain name is multifaceted. By delving right into the approaches, fads, and ideal practices that underpin successful in-mold decoration processes, companies can open a realm of opportunities that not only elevate the aesthetic allure of their products yet additionally simplify production efficiency and boost customer involvement.

Material Option

Material option is a crucial facet of understanding in-mold decors, as it directly influences the quality and sturdiness of the final product. When selecting materials for in-mold decors, it is essential to take into consideration aspects such as compatibility with the molding procedure, the wanted aesthetic outcome, and the environmental problems the product will certainly face.

Furthermore, the selected material must possess good bond buildings to make sure that the decoration sticks strongly to the substrate during the molding process. Bond between the product and the design is important for preventing delamination and making sure lasting aesthetic appeal. Furthermore, products with high heat resistance are preferred for in-mold designs, especially for products that will certainly be subjected to elevated temperature levels during their lifecycle. By meticulously picking the appropriate material for in-mold designs, producers can enhance the overall quality and durability of their items, fulfilling the assumptions of both end-users and customers.

Style Innovation

A vital consider advancing the field of in-mold decorations is the continual expedition and implementation of design technology strategies. Design advancement plays a vital duty in boosting the visual allure, functionality, and overall top quality of items produced using in-mold decor processes. By integrating innovative layout elements, manufacturers can distinguish their products in the market, bring in customers, and stay ahead of rivals.

One of the essential facets of layout advancement in in-mold decorations is the integration of detailed patterns, structures, and graphics that were previously challenging to achieve with typical decoration techniques. Advanced innovations such as 3D printing and digital style tools enable designers to produce complex and in-depth designs that can be seamlessly transferred onto molded parts. In addition, the use of lively shades, metallic surfaces, and special results like gloss or matte structures can even more raise the aesthetic allure of in-mold decorated items.

Moreover, design innovation prolongs beyond appearances to include useful enhancements such as ergonomic forms, integrated attributes, and customizable elements that accommodate specific customer demands. By embracing layout technology, suppliers can open new opportunities for imagination, customization, and item distinction in the competitive landscape of in-mold decors.

Production Efficiency

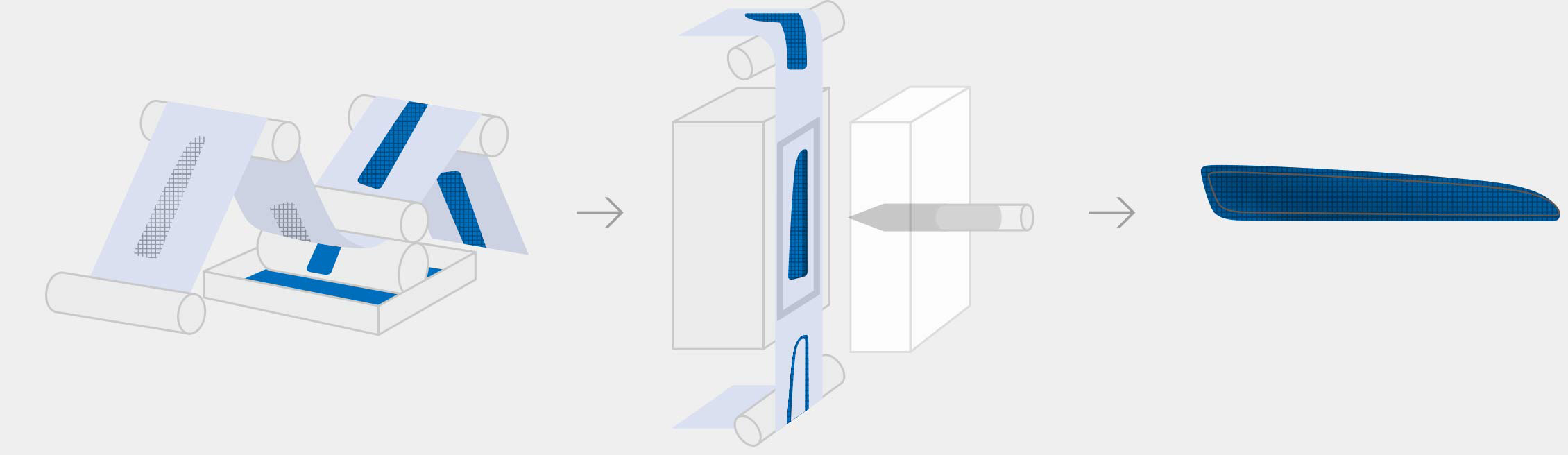

Effective manufacturing procedures are vital for converting the cutting-edge designs established in the field of in-mold designs into top quality ended up items that satisfy market needs and customer expectations. In the realm of in-mold decorations, production performance incorporates various crucial aspects that add to the overall success of the production process. One vital element is the optimization of mold design and tooling to make certain exact and smooth decor transfer onto the final product. By fine-tuning mold setups and spending in high-quality tooling read what he said products, manufacturers can improve effectiveness and consistency in production.

Furthermore, executing automation and robotics in the production line can considerably improve performance by streamlining repeated tasks and reducing the margin of error. Automation not only increases the production procedure however also improves accuracy and repeatability, causing a more uniform and high-quality final product. Taking on lean manufacturing concepts, such as just-in-time supply administration and waste decrease methods, can even more boost manufacturing effectiveness by lessening downtime and optimizing resource usage. In general, an alternative approach to production performance is paramount in maximizing the potential of in-mold design methods and accomplishing optimal cause the open market landscape.

Top Quality Control Steps

What are the essential techniques for ensuring rigid top quality control procedures in the realm of in-mold decors? Quality control steps are paramount in in-mold decor processes to ensure the manufacturing of premium and flawless completed products. One crucial technique is the execution of strenuous examination protocols at every phase of the production process. This includes performing comprehensive visual assessments, dimensional checks, and shade consistency evaluations to recognize any type of disparities or flaws early.

Using innovative modern technologies such as automatic examination systems can also improve the quality assurance process by giving exact and reliable data for analysis. These systems can spot blemishes that might be missed by hand-operated inspections, therefore enhancing total item quality and consistency.

Normal training and growth programs for staff members associated with the in-mold decoration procedure can also add to maintaining top quality criteria. By educating personnel on finest practices, top quality expectations, and the relevance of attention to information, business can foster a culture of quality consciousness throughout the organization.

Customer Charm

To boost the marketability of in-mold decoration products, comprehending and catering to consumer preferences play an important role in determining their allure and success. Consumer charm in in-mold decorations is influenced by various elements, consisting of layout looks, shade selections, toughness, and total performance. Consumers are increasingly seeking individualized and distinct products that mirror their uniqueness and design. Using customization alternatives such as personalized designs, shade variants, and textural elements can considerably improve the allure of in-mold design products.

Conclusion

In-mold designs offer a flexible and reliable means to enhance product appearances. Grasping in-mold decorations calls for an all natural strategy that considers all aspects of the production process to you could look here guarantee success.

In the realm of manufacturing, the art of in-mold decors stands as a crucial aspect of product style and production. Style innovation plays a crucial role in enhancing the aesthetic charm, performance, and total high quality of items made using in-mold decor procedures.One of the essential aspects of design advancement in in-mold decors is the assimilation of elaborate patterns, appearances, and graphics that were formerly testing to attain with standard decor approaches.Reliable production procedures are vital for converting the innovative styles developed in the field of in-mold designs right into high-quality ended up products that satisfy market demands and customer expectations. Using modification options such as personalized designs, shade variations, and textural aspects can considerably enhance the charm of in-mold decoration products.